roughing end mill feeds and speeds

Fullertons carbide end mills are designed to excel in profiling finishing roughing pocketing and slotting operations for a variety of materials including titanium super alloys hardened steels stainless steels steels cast iron graphite brass copper. We are a store where you can easily find and purchase High Quality End Mill Bits including high performance Solid Carbide EndmillsWe have broken the industrial tool catalog paradigm by creating two fast and easy methods to search for your milling BitYou can use the categories on the left or you can use the End mill filter search.

Be sure to keep this in mind when using one.

. Hardmill Threadmill Speeds and Feeds Hard Mill Speeds and Feeds. Therefore it only covers 2 variables. 2033 Innovation Way Hartford WI 53027 Toll-Free.

Special roughing end mills with serrations to break up chips are among the best tool types for removing material. You can of course use the exact same bit as with the Roughing Passes and there is still benefit to be had by doing things as described in this guide but depending on the model you are machining a ball nose end mill or a smaller sized end mill for more smaller details might be appropriate. However they do produce a poor finish when compared to standard end mills.

Many tooling manufacturers provide useful speeds and feeds charts calculated specifically for their products. Indexed End Mill - Endmills with replaceable cutting edges and steel bodies. Speeds.

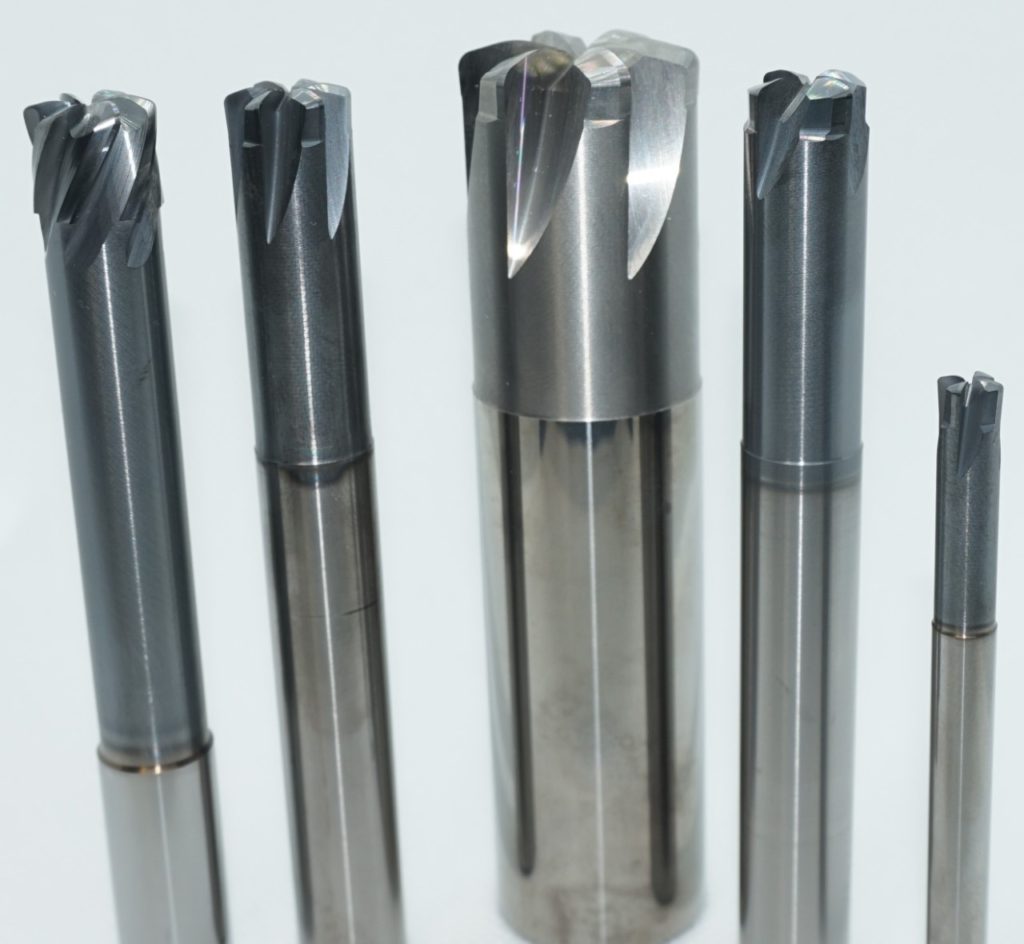

Choose from Fullertons selection of carbide end mills including ball-end corner radius-end square-end and more. Determining the right speeds and feeds for your tool and operation can be a complicated process but understanding the ideal speed RPM is necessary before you start running your machine to ensure proper tool life. The DM-2 and DT-2 Bob and Bryan talk about the new Haas DM-2 and DT-2 and show a great cutting demo that highlights the machines features like 2400 ipm rapids and tool changes in less than 1 second.

The Turbo Carb end mill is made of an application specific carbide to improve wear resistance and toughness in demanding applications. A final finish pass with a standard or finishing end mill will improve the surface finish. Apply coatings for higher feeds speeds and tool life.

How to Choose the Best Solid Carbide End Mill Design Machining Application. The processes that have this common theme are collectively called subtractive manufacturing in contrast to additive manufacturing which uses controlled addition of materialExactly what the controlled part of the definition implies can. PCD Diamond Ball End Mills.

Balance the diameter of a ball end cutter versus the rigidity. Designed for high speed roughing and finishing of complex contoured shapes in hardened materials. Feed InchTooth End Mill Diameter 18 316 14 38 12 58 34 1 Recommendation for Coated Tools.

But running work at proper feeds and speeds is the best way to cut clean holes and tap stainless steel most efficiently. For example Harvey Tool provides the following chart for a 18 diameter end mill tool 50308. Variable Flute for Steel Speeds and Feeds.

A basic Feeds and Speeds Chart like whats in your tooling catalog is a 2 dimensional entity. When making finish passes you would reduce this number to 10 especially when using a 116 ball nose end mill for detail carving. General Purpose Solid Carbide End Mills RoughingFinishing.

High Feed End Mill - Indexed end mill with an extremely low lead angle that directs most of the cutting force in the downward direction. Running a tool too fast can cause suboptimal chip size or even catastrophic tool failure. If space allows it use a helical motion when plunging into a pocket.

A customer can find the SFM for the material on the left in this case 304 stainless steel. These are the same tools we use here in our own state-of-the-art machine shop and we have video and cutting data for every tool. Feeds Speeds and Product Dimensional Data in the Palm of Your Hand.

Carbide HSS Cobalt. Carbide Rougher Feeds and Speeds. On Steels 45 HRC on Roughing use Coolant on Finishing Run Dry TiCN add 40 on.

Sophisticated feeds and speeds software lets you master a lot more variables than you could manage by hand. 6 Flute Speeds and Feeds. Running It Too Fast or Too Slow Can Impact Tool Life.

Variable Flute for Stainless Steel Speeds and Feeds. Composite High Feed Mills. Just click on the tool youre interested in to see a video of the tool cutting including feeds and speeds depth of cut and all the data you need to hit the ground running when your tools arrive.

The R refers to how far the tool will retract from the part in X when returning in rapid to the start of the cycle. A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds. General Purpose End Mill.

A center-cutting end mill has cutting edges that extend into the center of the tool which allows it to plunge into a material. While narrow-diameter drill bits must maintain a minimum speed to be effective wider bits especially when used to. Lightning fast and accurate the TRT100 fits in nearly every Haas mill and will help you cut cycle times and boost your shops efficiency.

Speed and Feed Calculator for Miscellaneous Applications. If possible use a feeds and speeds calculator or CAM program that properly accounts for these effects. Thread Mill Speed and Feed Chart.

Contouring End Mill for Hardened Materials Turbo-Carb Series 56. As a result the cutter must perform over a wide range of surface speeds and chip loads at different depths in the cut. They use multiple charts add columns and rules of thumb to cover a few more variablesmaybe 4 to 6.

Speeds. 4. Speeds FeedsSandwich.

Dagger Drill Carbide. These tools allow for higher cutting speeds due to shallow depths of cut and the relative inexpensiveness of inserts. The tooth design allows for little to no vibration but leaves.

The end of this tool is ground with a full radius equal to half of the tool diameter and the edges are center cutting. A non-center cutting end mill only has cutting edges on the side and requires either a pilot hole ramping or helical motion to plunge straight down. Machining is a process in which a material often metal is cut to a desired final shape and size by a controlled material-removal process.

Tapered Drill Reamer. Speeds Feeds Solid Carbide High Performance End Mills. 40 is the default which is good for most general pocketing and roughing passes when carving 3D objects.

G71 is our G-Code that lets the controls know that we wish to use a roughing cycle and that the following information applies to that. Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations. Variable Flute for Aluminum Copper and Brass Speeds and Feeds.

They can be single end or double end and they can be made from solid. A ball end milling cutter is also known as a ball nose mill. The U on the first line of code is the depth of cut of each roughing pass.

Solid Carbide End Mills Haimer

Speed Feed Recs Melin Tool Company

Technology Spotlight High Speed Trochoidal Tools

Speed Feed Recs Melin Tool Company

Everything You Need To Know About Endmills Basic Beginners Guide Accusharp Endmills Accusharp Cutting Tools Accusharp

End Mill An Overview Sciencedirect Topics

High Helix Carbide End Mill At Rs 3000 Unit Solid Carbide End Mills Id 20478637012

8 Ways You Re Killing Your End Mill In The Loupe

Solid Carbide Endmills High Performance Machining Long Tool Life Accusharp Cutting Tools Accusharp

7 Tips For Choosing The Right End Mill For The Job M M Sales Equipment

Hss Square End Mills Flat End Mills Hss End Mills Dic Tools

Basic End Mills Technical Information Msc Industrial Supply Co

An In Depth Look At Helical S Tplus Coating For End Mills End Mill Multi Layering

End Mill Tool With High And Low Helical Flutes And Related Method For Rough Cutting And Finishing A Workpiece Destiny Tool

Multiple Uses Of Chamfers Multiple Machinist Sharp Edge

4 6 Flute High Feed End Mills Epic Tool

Freud 87 308 3 Piece Fine Detail Cnc Router Bit Set Cnc Router Bits Cnc Router Router Bit Set

What To Know When Selecting An End Mill End Mill The Selection Machining Process